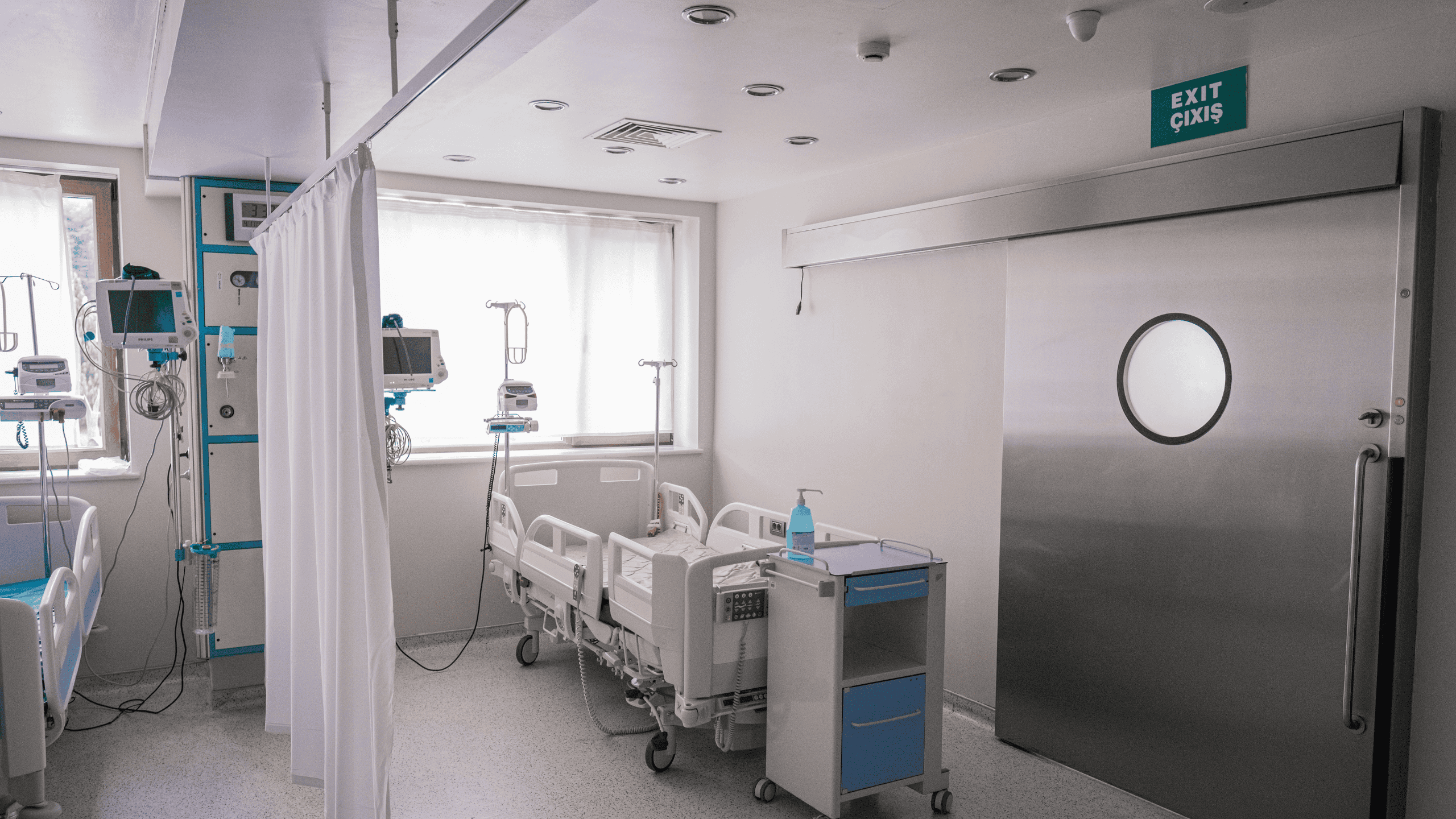

In the global healthcare industry, quality, reliability, and compliance are critical. At LisaMed, we specialize in manufacturing and exporting medical equipment for operating rooms and intensive care units worldwide. This article takes you inside our factory to explain how medical equipment is designed, manufactured, tested, and delivered to meet international standards.

Product Design & Clinical Requirements Analysis

Every medical device starts with a clear clinical purpose. Our engineering team works closely with hospitals, distributors, and OEM/ODM partners to understand real-world clinical needs.

During this stage, we focus on:

- Clinical application scenarios (OR, ICU, emergency care)

- Ergonomic design for medical staff

- Patient safety and comfort

- Compliance with international medical standards

For OEM and ODM projects, LisaMed provides customized solutions including appearance design, functional configuration, and branding options.

Raw Material Selection & Component Sourcing

High-quality medical equipment begins with premium materials. LisaMed carefully selects certified raw materials and key components to ensure durability and safety.

We focus on:

- Medical-grade steel and aluminum structures

- High-performance motors and actuators for hospital beds

- Reliable electronic components for monitors and anesthesia systems

- Antibacterial and easy-to-clean surface materials

All suppliers are strictly evaluated to ensure long-term stability and compliance.

Precision Manufacturing & Assembly

As a professional medical equipment manufacturer, LisaMed operates standardized production lines for OR and ICU equipment.

Our manufacturing process includes:

- CNC machining and metal fabrication

- Welding, polishing, and surface treatment

- Electrical system integration

- Modular assembly for efficient maintenance

Each workstation follows standardized operating procedures to ensure consistent product quality.

Quality Control & Functional Testing

Quality control is one of the most critical stages in medical device manufacturing. Every product undergoes strict inspections before leaving our factory.

Our testing process includes:

- Load and durability testing

- Electrical safety inspection

- Functional performance testing

- Visual and structural inspection

Products must meet both internal quality standards and international regulatory requirements before approval.

Certifications & Regulatory Compliance

LisaMed manufactures medical equipment for global markets, which means compliance is non-negotiable.

Our products are designed and produced according to:

- ISO quality management systems

- CE requirements for European markets

- Export standards for hospitals and distributors worldwide

We also support certification documentation for OEM and distributor partners entering local markets.

Packaging, Logistics & Global Delivery

After final inspection, products are professionally packaged to ensure safe international transportation.

We provide:

- Export-standard packaging

- Flexible shipping options (sea, air, land)

- Documentation support for customs clearance

- Global delivery coordination

LisaMed currently supplies hospitals, clinics, and medical distributors across multiple regions.

Why Hospitals and Distributors Choose LisaMed

Choosing the right hospital equipment manufacturer is crucial for long-term success. Clients work with LisaMed because we offer:

- Reliable manufacturing capacity

- OEM / ODM flexibility

- Strict quality control

- Competitive pricing

- Responsive after-sales support

Our mission is to deliver dependable medical equipment that supports better patient care worldwide.

Partner with a Trusted Medical Equipment Manufacturer

Understanding the medical equipment manufacturing process helps buyers make informed decisions. At LisaMed, transparency, quality, and partnership are at the core of everything we do.

If you are looking for a reliable medical equipment manufacturer or OEM/ODM partner, LisaMed is ready to support your project.