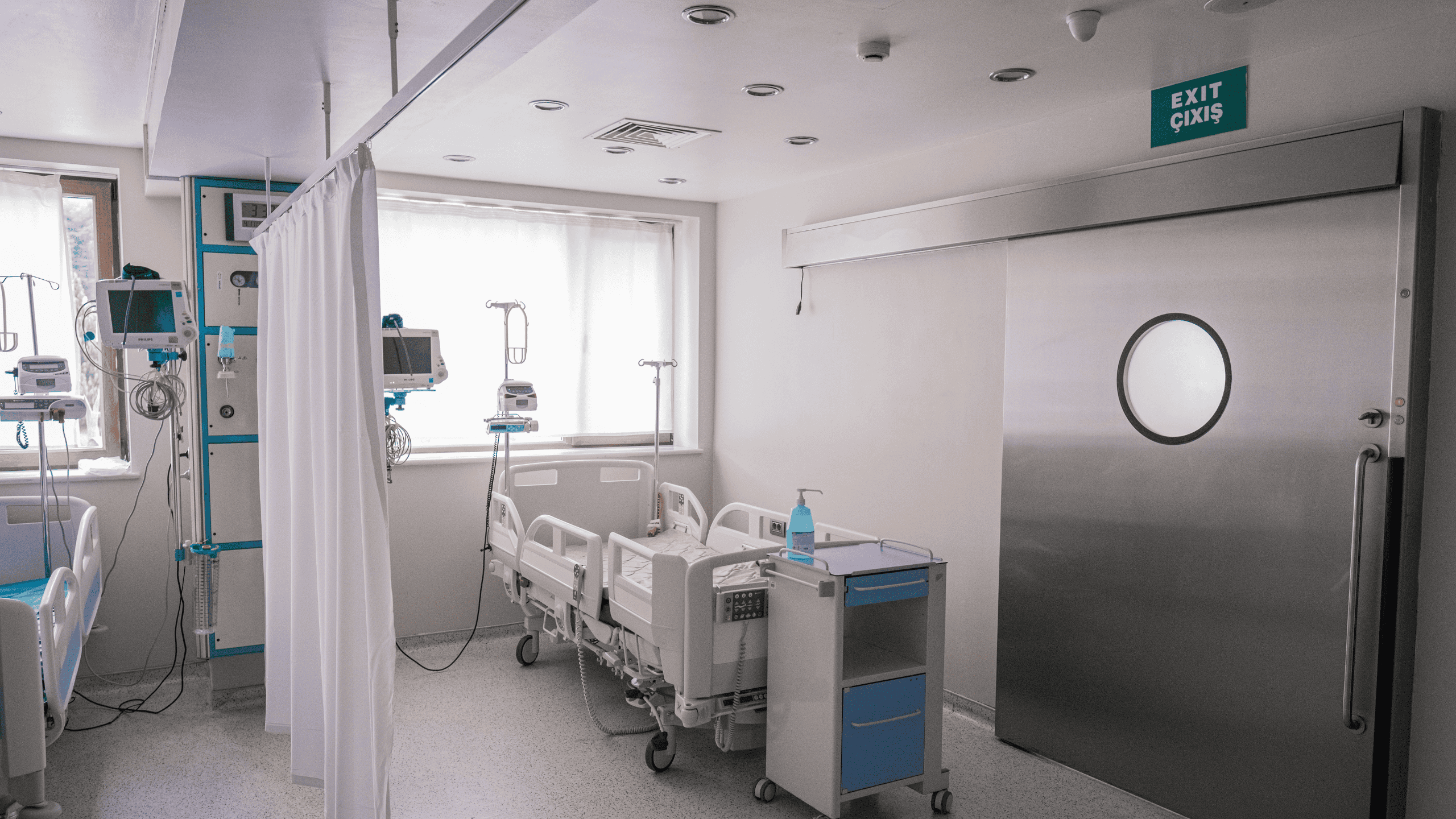

Choosing a reliable medical equipment manufacturer is a critical decision for hospitals, clinics, distributors, and medical brands. Product quality, regulatory compliance, and long-term support directly impact patient safety, operational efficiency, and project success.

This guide explains the key factors you should evaluate when selecting a medical equipment manufacturer for operating room (OR) and intensive care unit (ICU) projects.

1. Manufacturing Experience and Industry Focus

A reliable medical equipment manufacturer should have proven experience in medical device manufacturing, especially in hospital, OR, and ICU equipment.

When evaluating a manufacturer, consider:

- Years of experience in the medical industry

- Focus on critical care and hospital equipment

- Understanding of real clinical application scenarios

Manufacturers with specialized experience are more likely to meet international standards and hospital requirements.

👉 To better understand how professional manufacturers operate, you can read our detailed overview of the production workflow:

Medical Equipment Manufacturing Process

2. Quality Control System and Production Standards

Quality control is one of the most important factors when choosing a medical equipment supplier. A professional manufacturer should apply strict quality checks throughout the entire production process.

Key quality control steps should include:

- Incoming raw material inspection

- In-process quality monitoring

- Functional and safety testing

- Final inspection before shipment

For ICU and OR equipment, every unit should be tested individually, not just by random sampling.

3. Certifications and Regulatory Compliance

Medical equipment must comply with international regulatory standards. A reliable hospital equipment manufacturer should clearly explain which certifications their products meet and be able to provide supporting documentation.

Common certifications include:

- ISO quality management systems

- CE certification for European markets

- Compliance with regional import regulations

You can learn more about CE medical device regulations from the official European Union Medical Device Regulation (MDR) page:

https://health.ec.europa.eu/medical-devices-sector_en

4. OEM / ODM Capabilities and Customization Support

For distributors and medical brands, OEM and ODM services are often essential. A reliable manufacturer should offer flexible customization while maintaining consistent quality standards.

OEM / ODM capabilities may include:

- Product configuration customization

- Structural and appearance design

- Logo and branding integration

- Customized packaging solutions

If you are sourcing private-label or customized equipment, working with an experienced OEM/ODM partner can significantly reduce development risks.

👉 Learn more about our OEM and ODM capabilities here:

OEM / ODM Medical Equipment Solutions

https://lisamed.com/

5. Production Capacity and Delivery Reliability

Production capacity directly affects lead time and project execution. A professional medical equipment factory should be able to support both small-volume orders and large hospital projects.

Key aspects to confirm include:

- Stable monthly production capacity

- Ability to scale production for large projects

- Reliable supply chain management

- On-time delivery performance

This is especially important for turnkey OR and ICU projects where multiple equipment categories are delivered together.

6. After-Sales Support and Technical Service

Medical equipment requires long-term support. A reliable medical equipment manufacturer should provide clear and professional after-sales service policies.

Ask the manufacturer about:

- Warranty coverage and terms

- Availability of spare parts

- Technical manuals and training

- Remote or on-site technical support

Strong after-sales support ensures equipment reliability and reduces downtime during clinical use.

7. Communication and Long-Term Partnership

Beyond product quality, communication is a key indicator of reliability. A trustworthy medical equipment supplier should communicate clearly and professionally throughout the cooperation process.

Signs of a good manufacturing partner include:

- Transparent pricing and documentation

- Clear production timelines

- Willingness to share factory and certification information

- Long-term cooperation mindset

Reliable communication helps avoid delays and misunderstandings during hospital projects.

Why LisaMed Is a Trusted Medical Equipment Manufacturer

LisaMed is a professional medical equipment manufacturer specializing in OR and ICU solutions for hospitals and medical distributors worldwide.

We are trusted by partners because we provide:

- Focused expertise in critical care equipment

- Standardized manufacturing and testing procedures

- International certification support

- Flexible OEM / ODM services

- Turnkey OR & ICU solutions

Final Checklist for Choosing the Right Manufacturer

Before making your final decision, ensure that your medical equipment manufacturer:

- Has proven experience in hospital and ICU equipment

- Implements strict quality control systems

- Meets international certification requirements

- Offers OEM / ODM customization when needed

- Provides reliable after-sales support

Choosing the right medical equipment manufacturer is an investment in quality, safety, and long-term success.

FAQ Section

Frequently Asked Questions

Q1: What makes a medical equipment manufacturer reliable?

A reliable medical equipment manufacturer follows strict quality control procedures, complies with international certifications, maintains stable production capacity, and provides long-term after-sales support. Experience in hospital and ICU equipment is also essential.

Q2: How can I verify a medical equipment manufacturer’s quality standards?

You can verify quality standards by checking ISO and CE certifications, reviewing testing procedures, requesting factory audits, and evaluating whether each product undergoes functional and safety testing before shipment.

Q3: Why are OEM and ODM capabilities important when choosing a manufacturer?

OEM and ODM capabilities allow customization of product design, configuration, and branding. This helps distributors and medical brands differentiate themselves while maintaining consistent quality and compliance.

Q4: Should hospitals choose manufacturers or trading companies?

Hospitals and distributors often benefit from working directly with manufacturers because they offer better quality control, technical support, customization options, and more transparent production processes.

Q5: How long does it take to manufacture medical equipment?

Manufacturing lead time depends on product type, order quantity, and customization level. Standard equipment may take several weeks, while customized OEM or turnkey OR & ICU projects may require longer production cycles.